AIroboticsHumanoid Robots

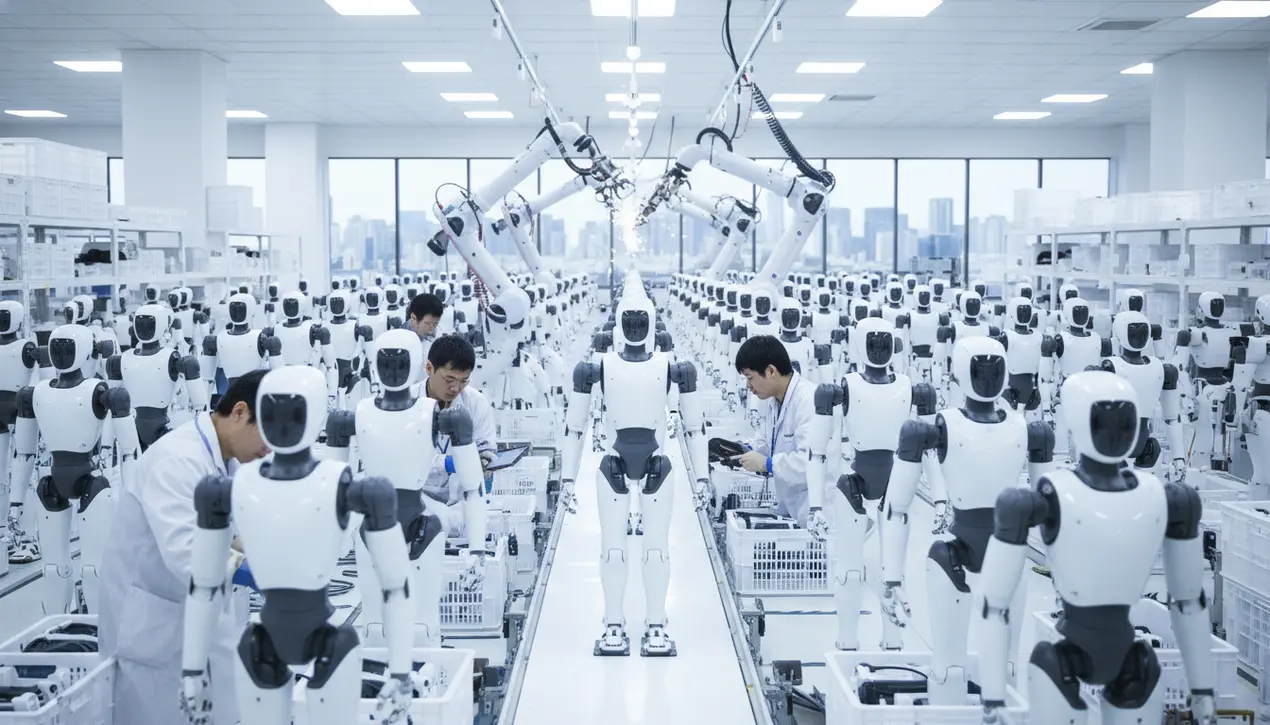

UBTech Plans Tenfold Increase in Humanoid Robot Production by 2026

DA

Daniel Reed

2 hours ago7 min read

UBTech Robotics has announced an ambitious production roadmap that signals a pivotal acceleration in the commercialization of humanoid robotics, planning a tenfold increase in assembly to as many as 5,000 units next year, with a target to double that figure to 10,000 by 2027. This aggressive scaling, articulated by the company's chief branding officer Michael Tam, is underpinned by the formidable scale economics of China's advanced manufacturing ecosystem, which is systematically reducing production costs by an estimated twenty percent annually.The Shenzhen-based firm, having progressed from delivering its first ten units last year to being on track for 500 industrial-grade humanoid deployments by the end of this year, is positioning itself at the forefront of a sector long dominated by research prototypes and lofty promises. This transition from boutique production to mass manufacturing mirrors the historical inflection points witnessed in other transformative technologies, such as the early automotive industry or the proliferation of personal computers, where cost reductions through manufacturing prowess unlocked vast new application domains.The core technological challenge has always been creating a machine that can operate reliably in unstructured human environments, a problem far more complex than the constrained tasks handled by traditional industrial arms. UBTech's Walker robot, like its competitors from companies such as Boston Dynamics and Tesla, represents a convergence of advancements in bipedal locomotion, tactile sensing, and AI-driven perception, but the true test will be achieving robustness and cost-effectiveness simultaneously.Experts in the field often draw parallels to the 'AI winters' of the past, cautioning that hardware, unlike software, faces immutable physical constraints and supply chain realities; a twenty percent annual cost reduction is a formidable claim that, if realized, would dramatically alter the economic calculus for automation in logistics, manufacturing, and even elderly care. The planned production volumes suggest UBTech is betting on a nascent but rapidly growing demand from industrial clients looking to automate complex, multi-step tasks that currently require human dexterity and cognitive flexibility.However, this bullish outlook is tempered by significant hurdles, including battery energy density, the high cost and reliability of actuators, and the 'sim-to-real' gap where AI models trained in simulation struggle with the infinite variability of the real world. The success of this scaling effort will not only validate China's strategic push into high-tech manufacturing but could also redefine global supply chains, potentially creating a new class of automation that is more general-purpose and adaptable than anything that has come before. The journey from 10 to 10,000 units is more than a numerical increase; it is a gauntlet thrown down to the entire industry, challenging the very notion of what is economically and technically feasible in embodied AI.

#UBTech

#humanoid robots

#production expansion

#industrial automation

#China manufacturing

#cost reduction

#featured

Stay Informed. Act Smarter.

Get weekly highlights, major headlines, and expert insights — then put your knowledge to work in our live prediction markets.

Related News

Comments

Loading comments...

© 2025 Outpoll Service LTD. All rights reserved.