- News

- auto-mobility

- New Rules Could Force Tesla to Redesign Its Door Handles. That’s Harder Than It Sounds

New Rules Could Force Tesla to Redesign Its Door Handles. That’s Harder Than It Sounds

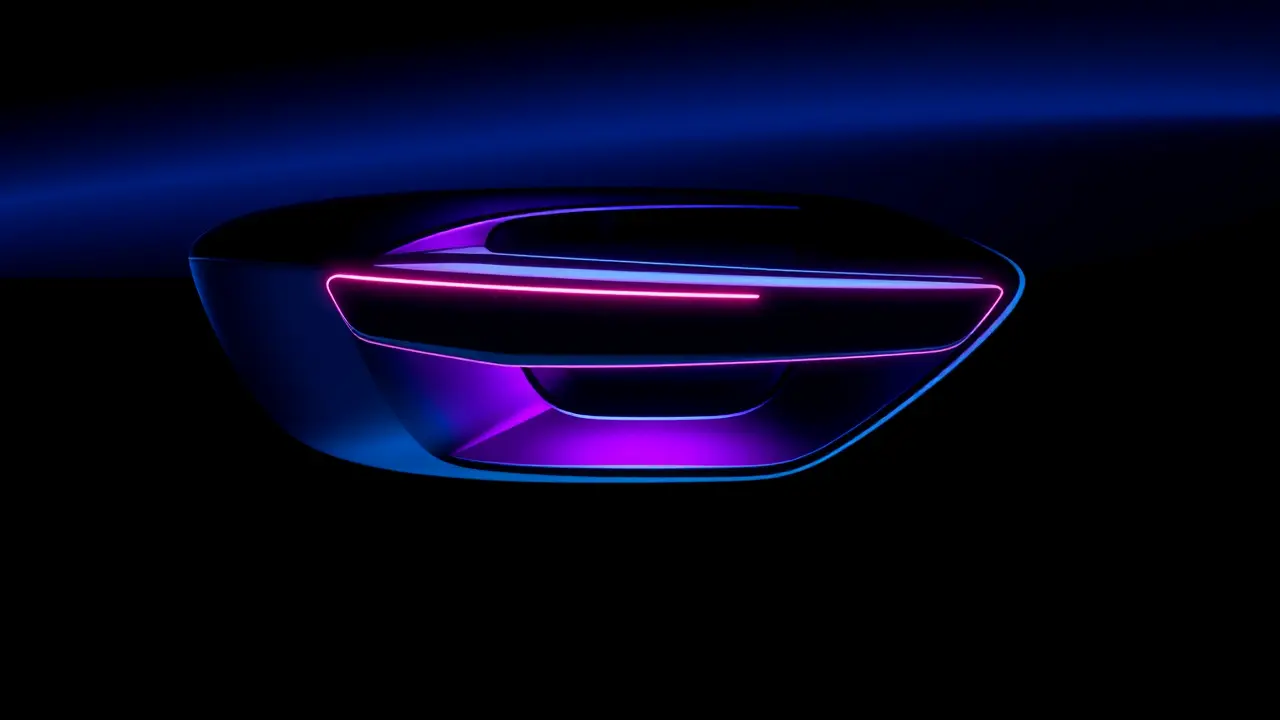

In a move that could fundamentally reshape automotive design philosophy, proposed regulations in China are taking direct aim at one of the most iconic, and controversial, features of the modern electric vehicle: the flush door handle. For Tesla, the pioneer of this minimalist aesthetic, the mandate represents not merely a regulatory hurdle but an engineering puzzle of cosmic proportions, a challenge as complex as plotting a trajectory to Mars.The core of the issue lies in a simple, safety-first principle: emergency responders must be able to access a vehicle's interior immediately and intuitively, without fumbling for hidden latches or waiting for electronic systems to power up. While this seems straightforward, for a company that has built its brand identity on seamless, futuristic surfaces, it strikes at the very heart of its design language.Redesigning a door handle is far harder than it sounds; it's not like swapping a bolt-on component. It necessitates a complete re-engineering of the door's internal architecture, recalibrating crash sensors, revalidating aerodynamic performance which directly impacts range, and re-tooling massive assembly lines, a process that can consume years and billions of dollars in a normal development cycle.The proposed Chinese regulations, reportedly giving manufacturers precious little time to comply, effectively drop a meteor into this meticulously planned ecosystem. We've seen this story before in the annals of automotive history, where form and function collide under regulatory pressure.Recall the era when sleek, protruding headlamps were mandated to be replaced by more pedestrian-friendly, recessed units, or when the dramatic tailfins of the 1950s were curtailed by new safety standards. Each time, the industry's artistic ambitions were forced to reconcile with the hard physics of public safety.For Elon Musk's Tesla, a company that operates with a startup's agility but on a global scale, this is its own version of the Apollo 13 mission—a sudden, unexpected problem requiring a brilliant, rapid-fire solution. The implications ripple far beyond Tesla's assembly plant.The entire supply chain, from specialized mold makers to electronic actuator manufacturers, would be thrown into chaos, scrambling to produce new components at a scale and speed that may not be physically possible. Competitors who have followed Tesla's lead into flush handles, from Lucid to Rivian and even established giants like Mercedes-Benz, are watching with bated breath, their own multi-year product roadmaps hanging in the balance. This isn't just a story about a car part; it's a high-stakes drama playing out at the intersection of global regulation, cutting-edge engineering, and corporate identity, a testament to how a single, seemingly minor rule change can force a technological titan to recalculate its entire trajectory, proving that even the most audacious visions must eventually comply with the laws of physics and bureaucracy on Earth.

It’s quiet here...Start the conversation by leaving the first comment.